Authored by Isabel McCord

Tips & Tricks to Winter-Proof Your Extrusion Operations with Southern Heat Corp

As winter approaches, it’s not just the temperature that drops—efficiency and production quality can also take a hit if your equipment isn’t properly prepared. Southern Heat Corp is here to help you keep your extrusion operations running smoothly all winter. From preventing equipment malfunctions to avoiding costly repairs, these winter-proofing tips will ensure your production stays on track, even in the coldest months.

-

Prepare Early with the Right Freeze Protection Products

Don’t wait until the first frost! Get ahead by installing freeze-protection products in the warmer months, making it easier to access key areas of your setup and avoid emergency downtime. Southern Heat Corp offers a comprehensive range of solutions, including:

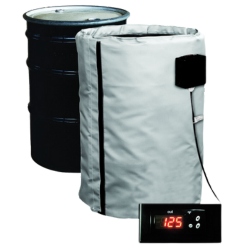

- Drum Heaters to maintain material flow and prevent blockages caused by thickened pellets.

- Heating Tapes for pipes, hoses, and valves—your winter-proof answer to freezing and blockages.

- Insulation Jackets to reduce heat loss and improve energy efficiency.

- Heated Hoses and Tubing for maintaining precise material temperatures throughout your entire system.

By being proactive, you not only prevent winter disruptions but also gain a chance to plan and prepare, ensuring all installations are correct and efficient.

-

Keep Materials Flowing with Drum Heaters

Winter weather can cause melted pellets to thicken, slowing down production. Southern Heat Corp’s drum heaters are the perfect solution. They wrap around your barrels, maintaining a consistent temperature to keep materials fluid and production steady. With our adjustable models, you get complete control over the heat settings, allowing you to handle winter temperatures without a hitch.

-

Protect Pipes, Hoses, and Valves with Heating Tapes

Winter is notorious for freezing and clogging pipes, hoses, and valves, which can cause costly disruptions. Think of heating tapes as a thermal scarf for your extrusion lines. They wrap around trouble spots to prevent freezing and keep your system running smoothly. Southern Heat Corp’s heating tapes offer precision warmth, perfect for preheating materials before they hit the extruder or maintaining temperatures during production.

-

Save on Energy Costs with Insulation Jackets

Heating is crucial, but retaining heat is just as important. Our thermal insulation jackets are designed to keep extruder barrels and molds at optimal temperatures, reducing heat loss and lowering energy consumption. This not only keeps your operations running efficiently but also saves you money in the long run.

-

Ensure Uniform Temperature with Heated Hoses and Tubing

Maintaining consistent temperatures throughout your extrusion system is critical, especially in winter. Heated hoses and tubing provide reliable warmth, ensuring materials flow smoothly from start to finish. Southern Heat Corp’s heated hoses and tubing prevent temperature drops, reducing the risk of clogs, freezing, or inconsistencies in your end product.

How Southern Heat Corp Can Help You This Winter

At Southern Heat Corp, we know winter poses unique challenges to the plastic extrusion industry. Here’s how we can support you:

- Expert Advice: Our sales engineers will assess your operations and recommend the best products to keep production running smoothly.

- On-Site Assistance: From product selection to installation, we provide hands-on support to ensure a seamless setup.

- Comprehensive Product Line: Whether it’s drum heaters, heating tapes, insulation jackets, heated hoses and tubing, or other freeze protection solutions, we have what you need to keep your extrusion process warm and efficient.

Don’t wait until winter slows you down—reach out to Southern Heat Corp today! Our team is ready to help you stay ahead of the cold and maintain production quality all season long.