Authored by Isabel McCord

Ungrounded vs. Grounded Thermocouples: Choosing the Right Option for Your Application

When it comes to measuring temperature in industrial applications, thermocouples are a go-to choice. However, not all thermocouples are created equal. The decision between ungrounded and grounded thermocouples can have a significant impact on the efficiency and accuracy of your processes. Let’s break it down by exploring the reasons for using each type, their common applications in the plastic industry, and any restrictions they might have.

- Why Use Ungrounded vs. Grounded Thermocouples?

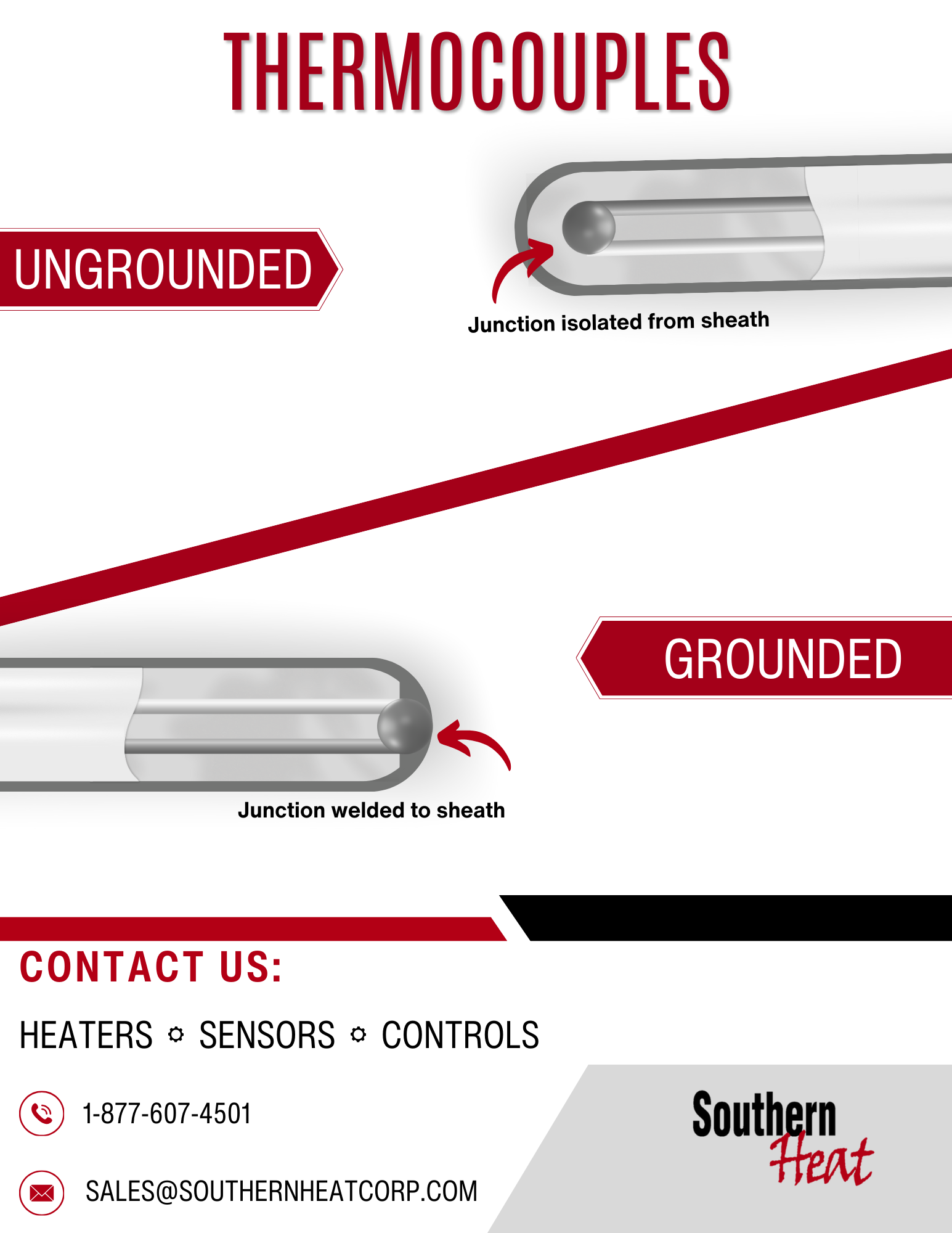

- Ungrounded Thermocouples: The junction is insulated from the metal sheath in ungrounded thermocouples. This design minimizes electrical interference, making them ideal for environments with high levels of electromagnetic noise. If your system involves sensitive electronic equipment or high-frequency signals, ungrounded thermocouples are the better choice. They also provide longer life in corrosive or oxidative environments due to the protective insulation.

- Grounded Thermocouples: Grounded thermocouples have the junction in direct contact with the metal sheath, providing faster response times. This design is perfect for applications requiring immediate temperature readings. Grounded thermocouples excel in dynamic environments with rapid temperature changes, ensuring precise real-time monitoring.

Learn how to test the difference!

- Most Commonly Used in the Plastic Industry

Maintaining consistent temperatures is critical for quality and efficiency in the plastic industry. Both ungrounded and grounded thermocouples have their place:

- Ungrounded Thermocouples: These are commonly used in processes like plastic extrusion where electrical interference from other machinery could impact accuracy. By reducing noise, they ensure more reliable readings for controlled heating.

- Grounded Thermocouples: Injection molding operations often use grounded thermocouples due to their rapid response times. In these applications, precise monitoring of quickly changing temperatures during the injection and cooling phases is essential for producing high-quality products.

- Restrictions to Consider

Each type of thermocouple has limitations that should guide your decision:

- Ungrounded Thermocouples:

- Slower response times compared to grounded thermocouples.

- May be more expensive due to the added insulation.

- Careful handling to avoid compromising the insulation.

- Grounded Thermocouples:

- Susceptible to electrical noise, which can distort readings in environments with significant interference.

- Not ideal for corrosive or high-moisture environments, as the exposed junction can degrade faster.

- Can create ground loops in systems with multiple grounding points, leading to measurement errors.

Making the Right Choice

Understanding the differences between ungrounded and grounded thermocouples is key to optimizing your processes. Consider your operational environment, the need for response time, and the potential for interference when making your decision. Whether you’re monitoring extrusion temperatures or ensuring precision in injection molding, the right thermocouple can make all the difference.

How Southern Heat Corp Can Help

At Southern Heat Corp, we specialize in providing top-quality thermocouples tailored to the needs of the plastic industry. From extrusion to injection molding, our team understands the unique challenges you face in maintaining precise temperature control. Here’s how we can support your operations:

- Expert Guidance: Not sure whether an ungrounded or grounded thermocouple is best for your application? Our Sales Engineers can help you assess your requirements and select the right solution.

- Custom Solutions: We offer a wide range of MRO and capital equipment designed to meet the specific demands of plastic extrusion, injection molding, and other processes.

- Reliable Products: Our thermocouples are built to withstand the harsh conditions of industrial environments, ensuring long-lasting performance and minimal downtime. Shop Southern Heat Thermocouples!

- Dedicated Support: From installation tips to ongoing maintenance advice, we’re here to help you get the most out of your temperature measurement equipment.

Need help finding the perfect thermocouple for your application? Contact our team at Southern Heat Corporation for expert advice and solutions designed to keep your plastic operations running smoothly.