TAKK Static Elimination in Plastics Processing

When plastic is processed—whether extruded, molded, wound, or cut—static electricity can build up. If left unchecked, this charge causes materials to cling, repel, attract dust, jam machinery, and even shock operators. In plastics manufacturing, controlling static is essential for quality, safety, and production efficiency.

TAKK offers solutions for eliminating static (i.e., neutralizing electric charge), especially in plastics operations.

Why Static Happens (A Brief Primer)

Before diving into each process, here’s a simple analogy:

- Imagine two neutral materials touching each other: nothing dramatic happens.

- But electrons may be displaced when you separate them (especially quickly or with friction). One may end up with extra electrons (negative), the other with fewer (positive).

- That difference in charge is static electricity.

- Like charges repel (− to − or + to +), opposite charges attract (− to +).

- In a plastics plant, this means sheets or films might stick or push away, dust can cling to surfaces, and parts can “jump” or repel.

- Even small individual charges add up when many parts or large surfaces are involved, creating significant effects

Source: TAKK Industrial Static Control and Static Elimination

Static Challenges & Solutions by Process

Here’s how static shows up in different plastics operations — and where to put static control devices to prevent problems:

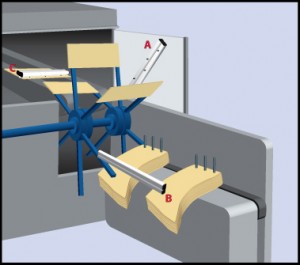

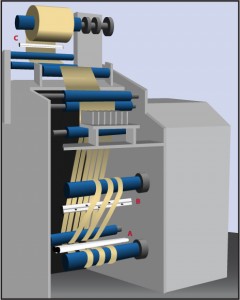

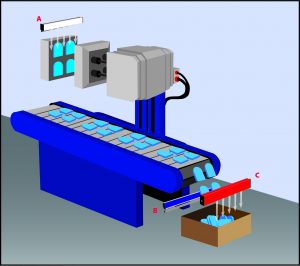

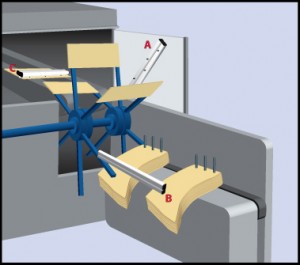

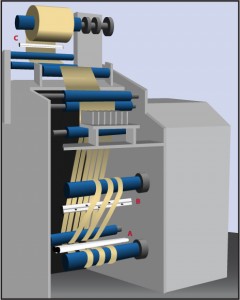

Bag Wicket

Problem: When you stack or collate plastic bags (for packaging, etc.), static can make them cling together or push apart. That results in poor stacking, misfeeds, and rejections.

Fix: Place static eliminators at key points:

- Where the bag enters the wicket (C)

- On the wicket mechanism (A)

- At the point of stacking (B)

This helps ensure each bag is neutral (no net charge), so they stack neatly.

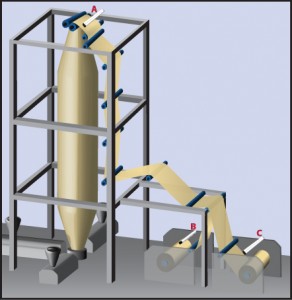

Slitting

Problem: In slitting, a roll of plastic (or film) is unwound and cut into narrower rolls. As the material is pulled and slit, static builds up. When rewound, layers may repel each other or misalign, harming roll quality.

Fix: Install a static eliminator before the rewind section. This neutralizes charges before layers are rolled back together.

Recommended Solutions: X-SERIES, Model 3024 DC, IonStorm XR2, Curtain-Air Ionizer, Vortex Ionizer Blower

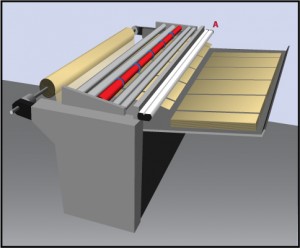

Sheeting

Problem: High speed sheeting (cutting into sheets) generates static from friction and rapid separation. Sheets may stick to parts of the machine or repel one another, causing jams or misalignment.

Fix: Mount a static eliminator just above and right after the sheeting area. This neutralizes the charge before stacking.

Recommended Solutions: X-SERIES, Model 3024 DC, Ion-Edge Model 400T

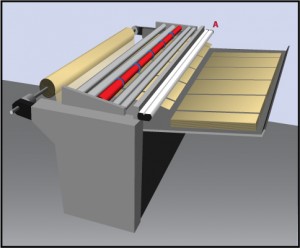

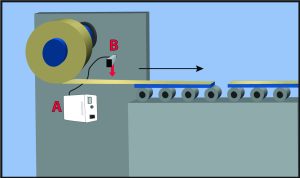

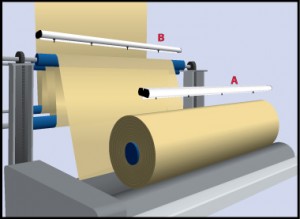

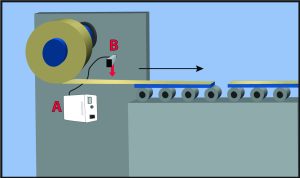

Winding (Unwind & Rewind)

Problem: When you unwind material from a roll, or rewind it after processing, static builds between layers, on surfaces, attracting dust or causing “jumpy” motion or mis rolls. Operators may also feel shocks.

Fix: Place static eliminators on top of the roll (on both unwind (B) & rewind sides (A)).

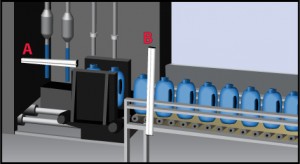

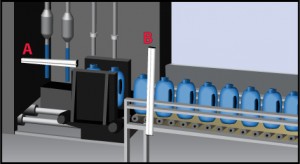

Blow Molding

Problem: In blow molding, molten plastic (the parison) exits a die into an open mold. It can carry a strong charge, which causes it to be attracted to the mold walls (or repel other parisons). This can cause distortions or rejections. After molding, the finished piece may still hold a charge and attract dust or shock operators.

Fix: Use static eliminators at two points:

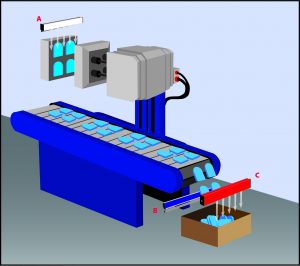

Film Extrusion

Problem: When you extrude film and it travels across rollers to winding, static accumulates — attracting dust, causing defects, and risking operator shocks.

Fix: Neutralize static at (A) the extrusion point, and (B, C) at key winding points.

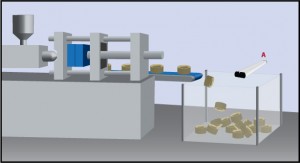

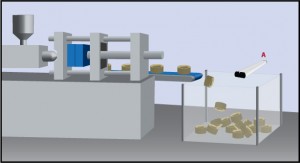

Injection Molding (General)

Problem: After molding, parts fall into bins or onto conveyors. Individually, they may carry small charges, but in aggregate, they create sizable static fields. This leads to dust attraction, soiled parts, and shocks to operators.

Fix: Mount a static eliminator at the collection bin or drop zone.

Recommended Solutions: X-SERIES, Model 3024 DC, IonStorm XR2, Curtain-Air Ionizer, Vortex Blower, Ion-Jet Super Air-Knife

Injection Molding — Small, Lightweight Parts

Problem: Tiny, intricate parts (for medical, pharma, and electronic components) often cling to mold ejectors or to the mold surfaces when open. Instead of falling freely into a bin, they stick, get misaligned, or jam the ejector mechanism.

Fix: Use a high-performance static eliminator bar (often air-assisted) mounted close to the mold face or ejector plane. This ensures parts are fully neutral and drop cleanly. Also, parts may need static removal while they’re on conveyors or in totes (further downstream).

In-Mold Labeling (IML) / Decorating

Problem: In IML, a printed label must be placed in a mold so that when the plastic is molded, that label becomes part of the final product. The label needs to “stick” to the mold at exactly the right spot until the mold closes. But if static is uncontrolled, the label may misplace, shift, or repel before the mold closes.

Fix: Use a static generator (to add a deliberate charge) plus charging bars or pinners to place a static charge on the label. That charge holds the label against the mold surface temporarily until the molding process embeds it permanently.

Recommended Solutions: Ionfix Static Generator, Static Charging Bar, Static Pinner

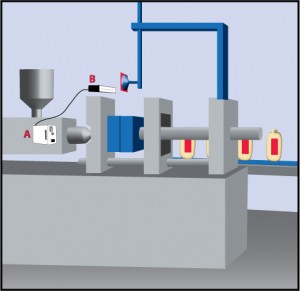

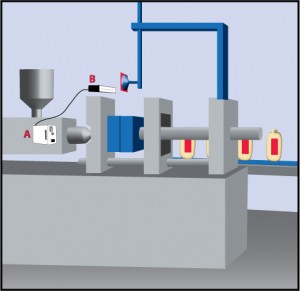

Plastic Resin Transport (Pellet Conveying)

Problem: Plastic (polymer) resin in pellet form is often pneumatically conveyed via pipes to storage hoppers or injection molding machines. The friction between pellets and pipe walls charges both. This static can cause:

- Cloggings (pellets stick)

- Slowed transport

- Erratic feed to the machine

- Electric shocks when operators touch the piping

Fix: Use a ring ionizer (designed for piping) inserted at strategic points in the conveying line to neutralize static as pellets pass.

Recommended: 3024 DC Ring Ionizer

Applying Protective Sheets to Metal / Plastic

Problem: Many finished plastic or metal sheets are covered with liner or “interleaf” sheets to protect surfaces during shipping. Common methods like adhesives or tapes are slow, messy, or expensive. Also, liners must be placed precisely. But static can cause misplacement or incomplete adhesion.

Fix: Use an electrostatic charging system (static generator + charging bar or pinner) to charge the liner so it’s gently pulled onto the sheet without adhesives — non-contact, fast, clean.

Recommended Solutions: Ionfix Static Generator, Static Charging Bar, Static Pinner

Putting It All Together: Why This Matters

By strategically placing static elimination devices during plastics processing, manufacturers can:

- Reduce defects and rejects

- Avoid machine jams and downtime

- Minimize contamination (dust, particles)

- Preventing operator shocks

- Maintain consistent product quality

At Southern Heat Corporation, we understand how important precise, reliable equipment is to your plastics processes. Whether you’re looking to improve production quality or reduce downtime, we provide the heating solutions that keep your systems operating at peak performance — and help you tackle challenges like static control head-on.

Learn more about how Southern Heat can support your operations: Contact us.

Coil Heaters: Precision Heat in Compact Spaces

Coil Heaters: Precision Heat in Compact Spaces

Watlow DIN-A-MITE A Power Controller

Watlow DIN-A-MITE A Power Controller